All the equipment manufactured by us can be available in different configurations and various optionals:

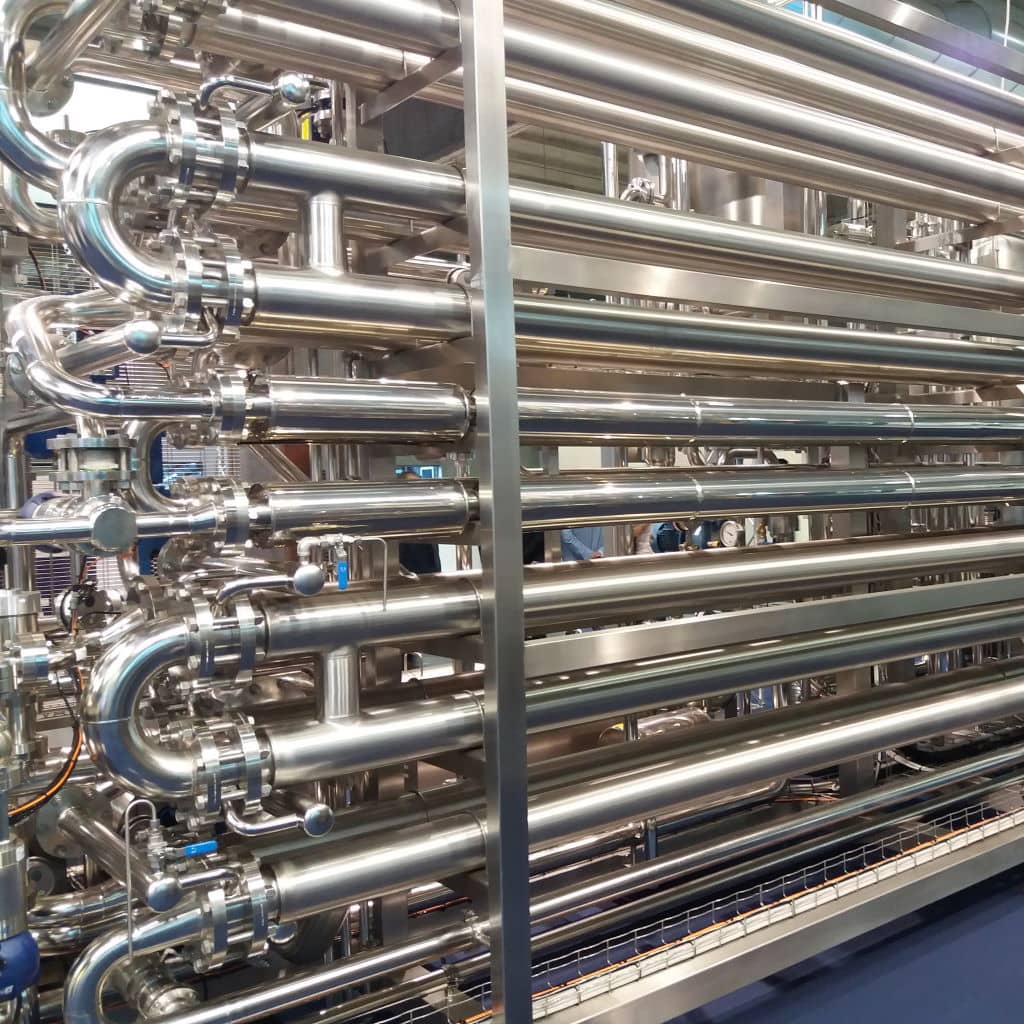

Thermoconditioning systems

- HONEYCOMB systems: economical and with operating pressures up to 3 Barg

- DUCT systems: high performance systems with operating pressures up to 1.5 barg

- CAVITY system: with high inertial effect, mass homogeneity of the temperature over the entire exchange surface, operating pressure up to 0.5 barg

Thermal insulation with cladded covering

- Thermal insulation of the cylindrical shell with rigid polyurethane foam, applied in double-layer sheets, with staggered joints, with a total thickness of about 100 mm and with a foam density of 35 kg / mc, protected on both sides by bitumen paper;

- Fixing of the plates with steel straps;

- Thermal insulation of roof and bottom with rigid polyurethane foam cast in the cavity, thickness 100/150 mm, density 40/50 Kg / mc;

- Thermal insulation of the legs with polyurethane foam c.s. cast inside them;

- Finishing in stainless steel sheet AISI 304;

- Overlapping joints with male edge;

- Fastening with rivets and TIG welding points;

- Rounded wedges execution for roof and bottom;

- Flanging of connections and sleeves;

- Sealing with gray adhesive silicone;

- Embossed external finishing.

Thermal insulation with welded cover

- Thermal insulation of the cylindrical shell with rigid polyurethane foam, applied in double-layer sheets, with staggered joints, or by direct injection of polyurethane foam for a total thickness of 100 mm and with a foam density of 35 kg / m3;

- Thermal insulation of roof and bottom with rigid polyurethane foam cast in the cavity, thickness 100/150 mm, density 40/50 Kg / mc.